Product introductionindustrial plastic crusher with auto recycling and mixing system is used for crushing Large-scale plastic and mixing new materials together with crushed material.

Different cutters of plastic crushers:1. Claw-shaped cutters

Different cutters of plastic crushers:1. Claw-shaped cutters have better effects on large plastic head materials or materials with higher hardness, such as material heads, shoe lasts, etc.

2. Flat cutters are suitable for all kinds of blow-molded parts, hollow products, and various film products, such as PET bottles.

3. special Cutters for Hollow plastic:Special patent front-positioning blade design especially for large hallow material like bottles and barrels, the rotary blades and stationary blades are settled with a V-shaped angle leading the crushing subject into rotary center, with large cutting angle, excellent efficiency, even flake output and less powder occurred. Application: It is especially efficient for hollow barrel, PET barrel, paint barrel, chemical barrel and so on.

4. Flake Cutters are suitable for crushing ordinary sheets, pipes, profiles, plates and packaging materials, and other plastic products and sprue openings.

Additional parts for plastic crusher: auto recycling and mixing system1. auto recycling system for plastic crusherThe auto recycling system is used to automatically convey crushed materials into the mixer, Save labor costs and increase production. In addition, plastic crusher is also can design as soundproof kind,avoid workshop noise.

besides, If you feel that the crushed material contains too much powder, you can add a powder screening device.

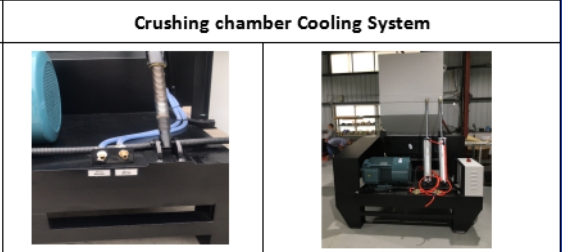

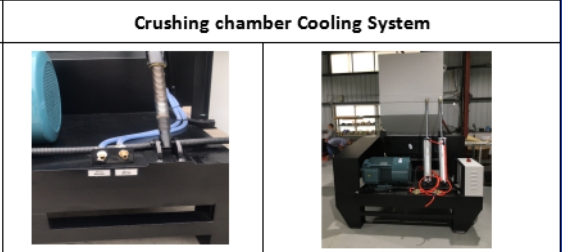

Last doesn't mean it's not important: 30hp,50hp, 75hp and 100hp plastic crushers are equipped with cooling system for crushing chamber.

Last doesn't mean it's not important: 30hp,50hp, 75hp and 100hp plastic crushers are equipped with cooling system for crushing chamber.

2. Mixing system for plastic crusher

2. Mixing system for plastic crusherThe Mixing system is used for mixing new materials together with crushed material.

Besides, the Mixing system is also can be equipped with drying system.

Besides, the Mixing system is also can be equipped with drying system.