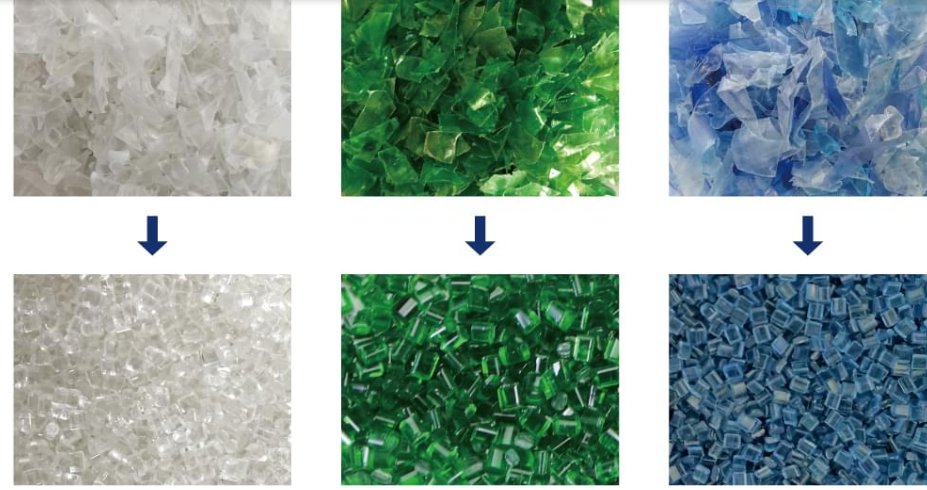

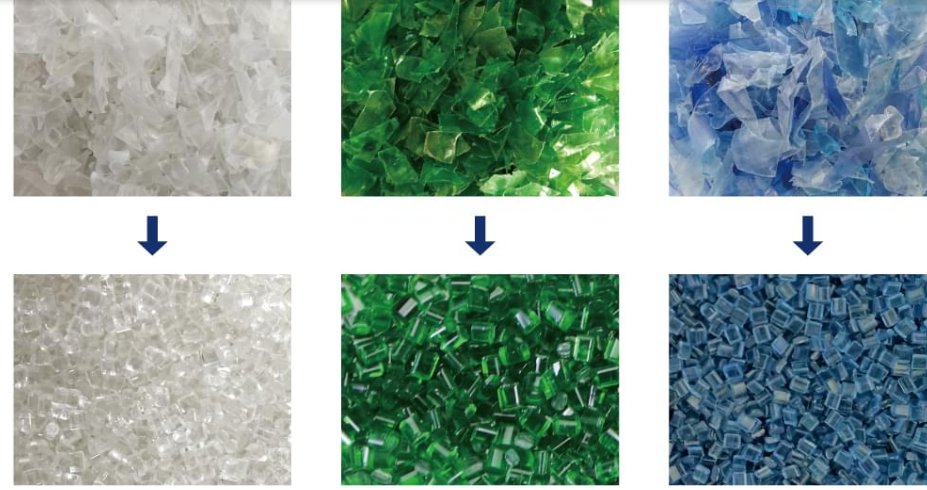

Description of PET pelletizing production line:

The PET pelletizing production line adopts a parallel twin-screw extrusion strand extrusion pelletizer, which has excellent mixing performance and good self-cleaning performance. It does not need to use a complicated pre-crystallization drying system, which can effectively control the viscosity of PET and reduce the IV. It is very small, and then adding appropriate additives can achieve a chemical viscosity increase.

The bottle flakes go through a vacuum system in the process of double-cutter mixing, drying, and extrusion to ensure that the viscosity is very small, and the IV is less than 0.03. With water stretch and pelletizing, the PET pelletizer adopts PLC control to realize production automation.

Features of PET pelletizing equipment:

1. Screw building block structure, full meshing screw, good self-cleaning, good exhaust effect.

2. The PET pelletizing equipment adopts an integral high-speed alloy cylinder, which is wear-resistant and corrosion-resistant.

3. The electrical control adopts imported components, which makes the industrial control stable and saves energy consumption.

Application of PET pelletizing equipment