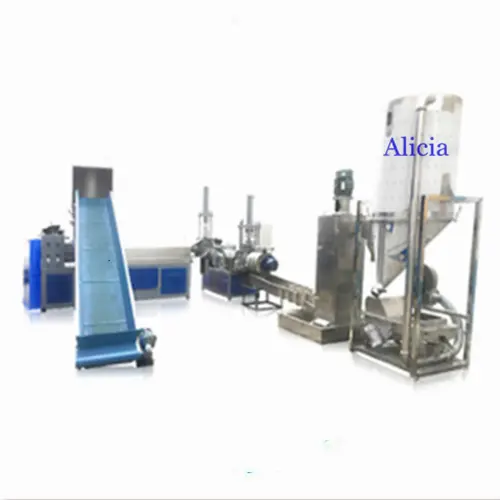

PE LDPE HDPE LLDPE film recycling and pelletizing production line

Description of PE LDPE HDPE LLDPE film recycling granulator:

The film recycling pelletizing machine adopts a production mode of crushing, hot-melt extrusion, pelletizing, and drying, which solves the manual feeding hazard caused by soft throwing materials with a low bulk density such as films and woven bags during the recycling and pelletizing process. Problems such as extremely high performance, the small output of forced feeding, high manual consumption for crushing and extruding split operation, the uneven particle size of stranding and cutting, easy to break, and other problems. The film granulation equipment adopts the method of compaction and crushing. After the material enters the compactor, it is cut and crushed by the bottom cutter head and is driven by the high-speed cutting of the cutter head to generate heat, which causes the material to shrink by heat to increase the bulk density of the material and increase the feeding volume. This kind of process is a great help to increase production capacity.

Features of PE LDPE HDPE LLDPE film pelletizing line:

1. High efficiency

Compared with the original design, the output of the film pelletizing line produced by Preh Machinery has increased by 20%.

2. Low energy consumption

Compared with the original design, energy consumption is reduced by 15%.

3. Highly automated

The plastic film granulator requires only 2 staff.

PE LDPE HDPE LLDPE film granulation equipment application industry:

Suitable for PE, HDPE, LDPE, LLDPE plastic materials.

Material shape: film, bag, non-woven fabric, (PE, PP) recycled materials

Material type: (roll, loose, bundled), the material comes from scrap, industrial waste film, and water-washed film.

Note: According to different material properties, different auxiliary equipment is required.