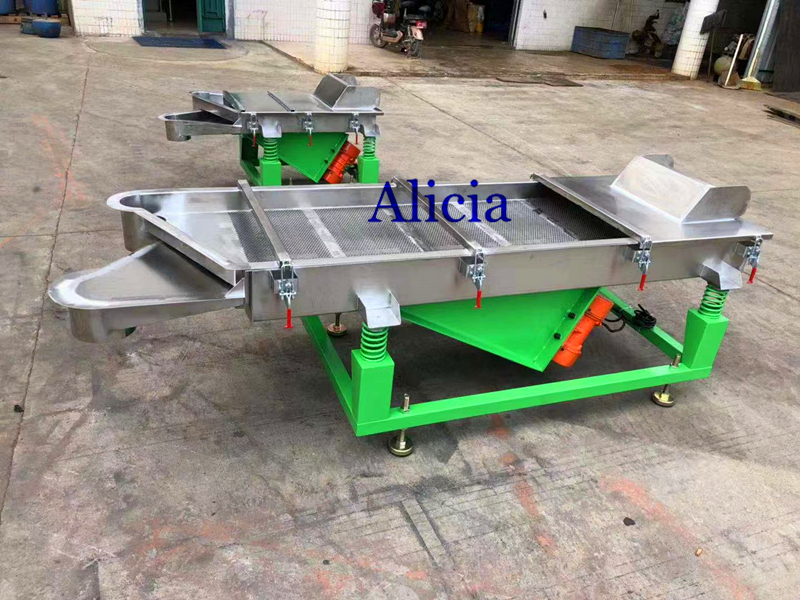

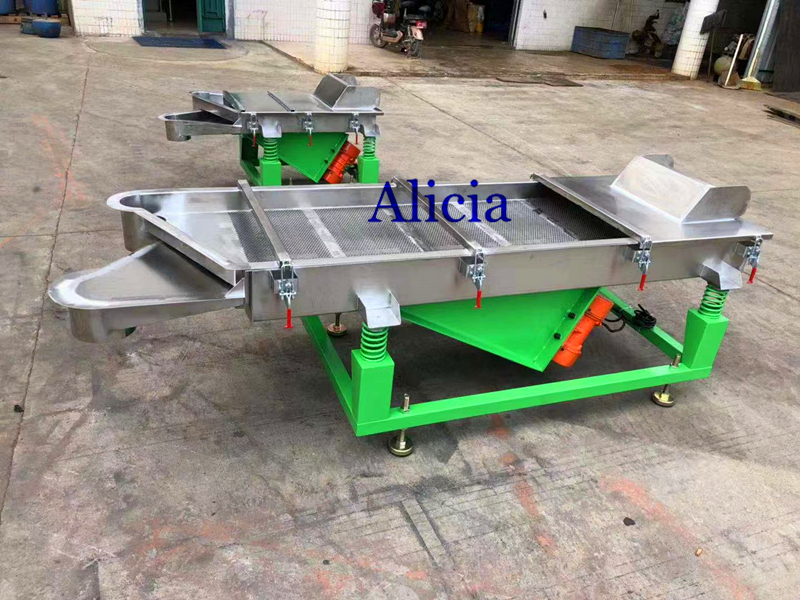

vibrating screens are used to screen plastic granules during the plastic recycling process. This screen filters out any impurities and powder mixed with the granules to ensure the granules are uniform. This vibrating screen requires an exceptionally lower power consumption of only 250W in its motor. In addition, this screen features a low noise operation, which in turn facilitates a comfortable production environment.

Specifications for vibrating screen

Specifications for vibrating screen

Output: 300 kg/h

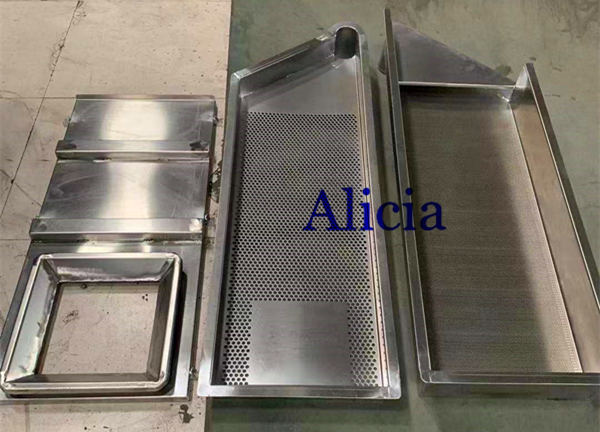

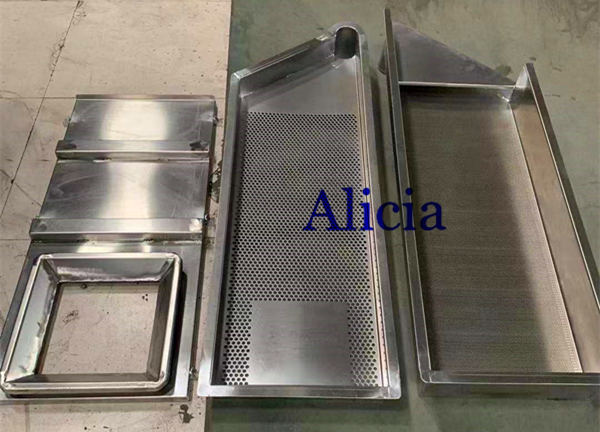

The size of the area with holes: length 940mm, width 370mm [count the top 440mm], overall width 600mm, length 1.3 meters

Material: 304 stainless steel plate

The first layer of mesh 8mm

The second layer 2.0mm

Thickness 1.5mm

Motor 0.12kw Voltage: 380V/3phase/50hz

The feed inlet is 60 cm above the ground (adjustable range +-8 cm)

Machine weight: 120KG

This linear vibrating sieve is 2 layers for classifying plastic pellets. It’s for filtering out fines (powder) and then the longs/irregular pellets.

The plastics from the pelletizer are screened and discharged into a box. Since the height of pelletizer and box has been fixed, the customer customized the feeding inlet and discharging outlets height of the linear vibrating screen.