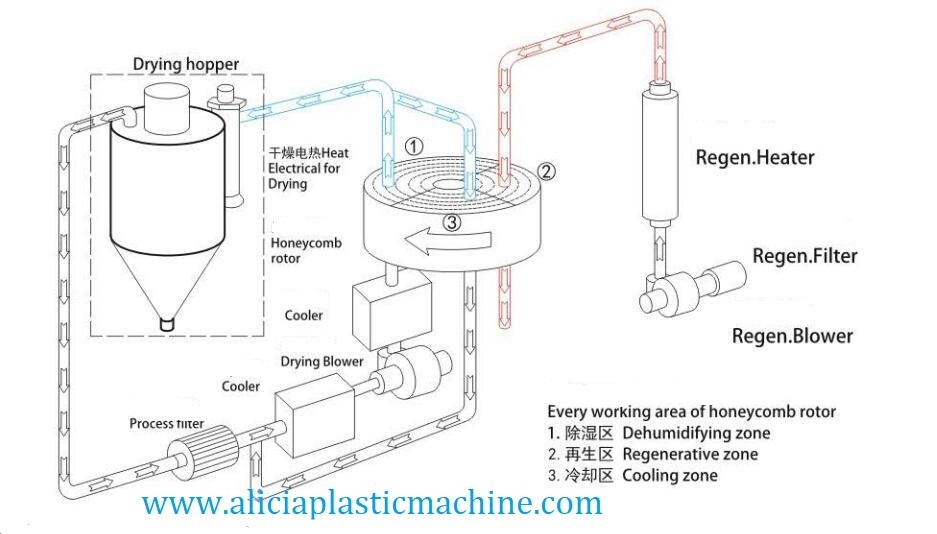

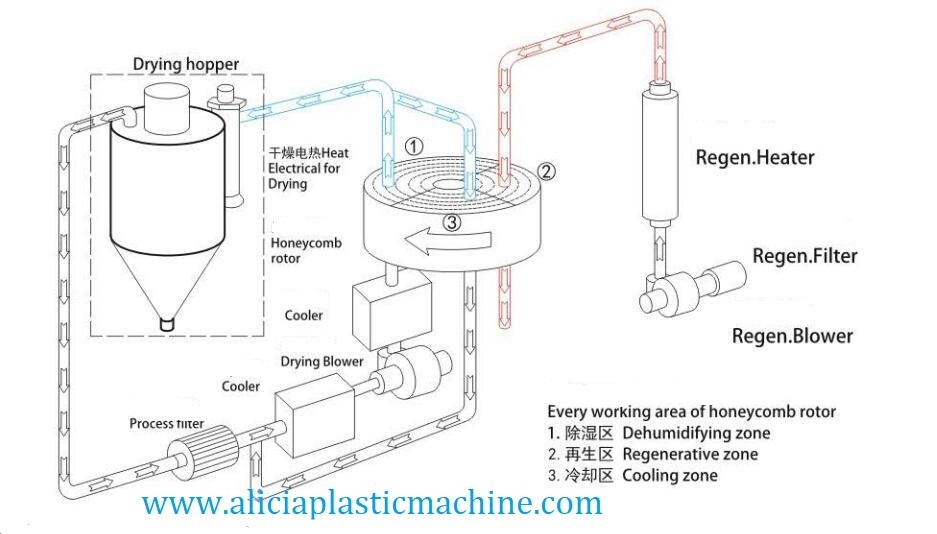

Applications:The main components of the honeycomb dehumidifier are all imported components, carefully selected materials, and assembled with good workmanship. The main purpose of the machine is to cooperate with the hot air hopper dryer to perform high-efficiency dehumidification and drying operations on highly hygroscopic engineering plastics (such as PA, PC, PBT, PET, etc.). Adopt P.I.D microcomputer temperature control system, LCD display, easy to operate. Adjustable honeycomb wheel rotation speed. It adopts double condenser structure to ensure lower return air temperature and dew point. The honeycomb can reach a dew point below -40°C, and can reach a dew point of -50°C or even lower under enhanced configuration. Optional PLC control with LCD touch human-machine interface. An optional dew point meter that can monitor the dehumidification effect of the machine at any time is available. The machine occupies a small area and is easy to move. The machine can be replaced at will.

1. Improve the flow, detachment or wet dispersion problems caused by hygroscopic agents;

2. Long life, washable, the base material of the runner is inorganic ceramic fiber, which is acid, alkali and corrosion resistant, and can withstand high temperatures of 1000 to prevent fire. Because the adsorbent is made of upper crystal, it can be cleaned with water or solvent without loss of performance, and the average life is more than 10 years.

3. The base material and silica gel are completely chemically crystallized, and there is no problem of loss of silica gel powder due to insufficient binding force caused by the soaking wheel;

4. Improve the shortcomings of granular molecular sieve drum type and rotary disk dehumidifiers because the powder after the molecular sieve is damaged enters the drying cylinder with the drying wind;

5. Large adsorption area and small pressure loss;

6. Using microcomputer PID automatic calculation controller, it is more energy-saving.

7. There are special solutions for raw materials with high oil content and dust.