1. Introduction of chiller for fermentation tank

Fermentation of dairy products and wine is usually a sterile process. During the fermentation process, the temperature in the fermentation tank keeps rising. If the temperature cannot be controlled in time, it may cause the fermentation body to deteriorate or produce bacteria, which will affect the normal fermentation. In addition, If the temperature of the fermenter is too high, it is also possible to burn out the heating circuit. The chiller for fermentation tank is used to provide continuous cooling water for the fermentation tank to ensure that the water temperature is between 3 and 25 °C. While protecting the normal operation of the equipment, it can also cool the fermentation liquid in the jacket and effectively control the fermentation temperature. To ensure the normal progress of fermentation. It is widely used in the cooling of small biological cell reactors (fermenters), and the sandwich chiller is used for temperature control in the experimental process to ensure that the fermentation quality will not be affected by temperature.

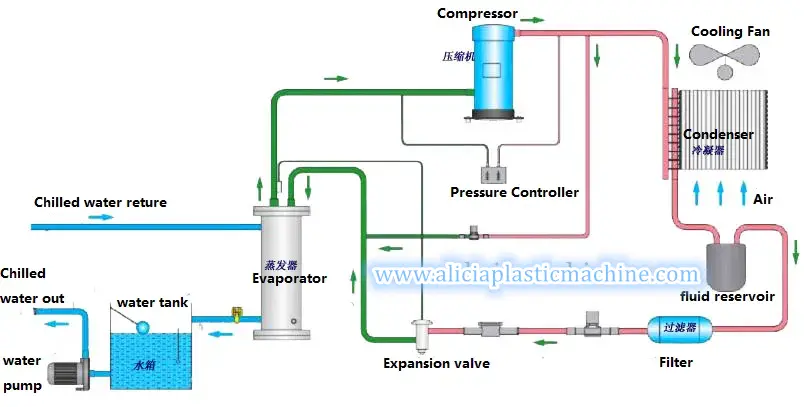

2. Working principle of chiller for fermentation tank

The chiller for fermentation tank first injects a certain amount of water into the internal water tank of the machine during the operation, cools the water through the chiller refrigeration system, and then injects the low-temperature frozen water into the equipment that needs to be cooled by the water pump. The heat is taken away, and the high-temperature hot water is returned to the water tank for cooling again, so as to circulate and exchange cooling to achieve the effect of cooling the equipment.

Its working principle is vapor compression refrigeration, that is, it uses the principle of absorbing heat when the liquid refrigerant vaporizes and releasing heat when the vapor condenses. In refrigeration technology, evaporation means that the liquid refrigerant turns into a gas when it boils. The process of changing from a liquid state to a gas state can only be achieved by absorbing heat energy from the outside world, so it is an endothermic process. The temperature at which the liquid refrigerant evaporates and vaporizes is called the evaporation temperature. liquid.

3. Features of chiller for fermentation tank:

The chiller for the fermentation tank adopts an air-cooled fully enclosed refrigeration unit, and the intelligent control refrigeration system is automatically turned on. The refrigeration system of the fermentation tank chiller has multiple protection devices such as delay, overheating, and overcurrent. The circulating pump can output the cold liquid in the tank, cool or thermostat the experimental container outside the machine or establish a second constant temperature field. The fermentation tank chiller has the function of microcomputer software lock, which can lock the set value of each parameter of the system, and irrelevant personnel cannot change the set parameters. It is completed by pressing the touch soft key on the microcomputer intelligent controller, and the operation is simple. It is easy to use and can work continuously.

4. Pay attention to the problems with the chiller for fermentation tank:

When using a chiller, you need to pay attention to the following issues:

1. Whether the cooling capacity of the chiller is suitable for the calorific value of the fermentation tank

2. What is the temperature control accuracy requirement of the chiller?

3. Is the pump head flow of the chiller sufficient?

4. What type of interface should the chiller choose to connect to the fermentation tank?