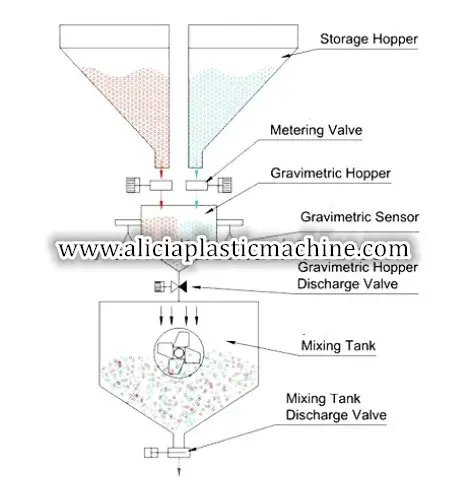

Working principle for Plastic granule gravimetric blender:When the machine starts to work, the storage hopper metering valve is opened, and the raw materials fall into the weighing hopper. When the machine starts to work, the storage hopper metering valve is opened, and the raw materials fall into the weighing hopper. Also - the storage hopper metering valve is opened. This cycle, when the need to mix raw materials are falling into the weight of the weighing hopper, and the weight of the weight hopper after reaching the preset value of the weighing hopper close valve opened, raw materials in the mixing bucket when the stirring leaf began to stir when the weighing hopper raw materials all fall into the mixing bucket after the weighing hopper close valve closed. The stirring blade shall continue to be stirred for a period of time, and the closing valve of the stirring drum shall be opened after the stirring is uniform. The raw material falls into the storage barrel or the injection molding machine so that a working cycle is completed.

Product Details for Plastic granule gravimetric blender:

Siemens Electrical

Adopt the world-famous brand ximen] son electrical components, stable performance

PLC Controller

Graph display, touch screen operation, reliable performance, simple maintenance; The controller standard configuration USB interface, can be mixed rice ratio data saved in the U disk, convenient production quality control.

Metering valve

Adopt side pull type blanking valve, blanking precision is more accurate, blanking proportion can be adjusted, simple maintenance, convenient replacement.

Weighing inductor

Celestron weighing sensor from USA and FESTO solenoid valve from Germany has the function of automatic optimization, adjustment compensation, and vibration prevention.

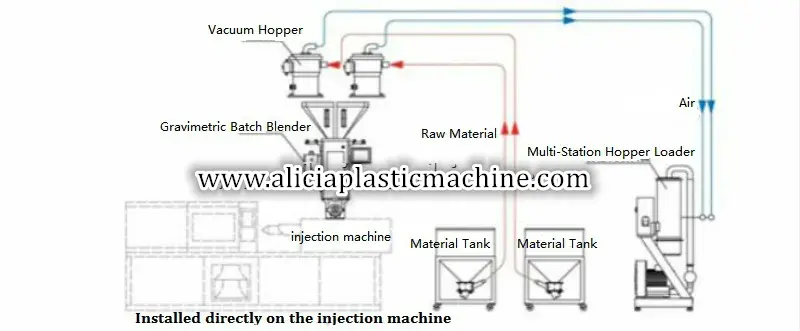

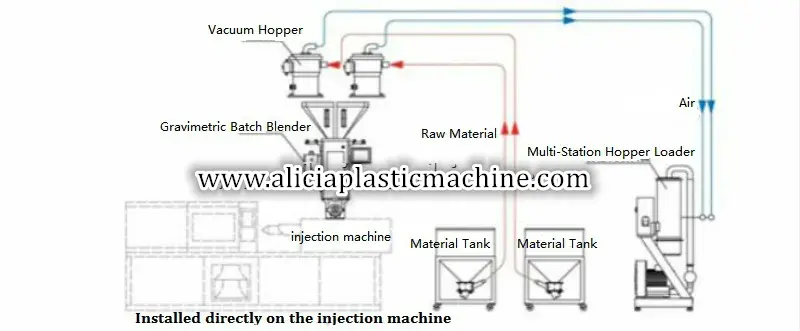

Product features for Plastic granule gravimetric blender1. Single-chip microprocessor has a stronger function, smaller size, and strong anti-interference ability2. The set data will not be lost after the EEPROM cuts off the power supply, and the battery is free3. Man-machine interface state display touch-type keyboard data input is more convenient but also can store a large number of formula data (500 groups)4. High speed and high precision AD grasp weight5. After all materials have been gravity metered, all materials have been gravity metered6. Proofread the data and the raw materials used7. It can be directly installed on the molding equipment, but the transfer base should be purchased;8. For ground installation, a combination of the pneumatic cutting valve, tripod storage barrel, and suction box should be selected.

Product application for Plastic granule gravimetric blender:The weighing type material mixing machine is suitable for precise mixing of various raw materials according to the weight ratio on plastic injection, pressing, or hollow molding. The controller of this series of products adopts the Germany Siemens PLC control system and adopts an advanced batching algorithm, which can be automatically calibrated when starting up each time to ensure accuracy and accuracy, easy to learn, and convenient to operate. This series of products using a high precision weight sensor to make the batch mixing ratio difference (depending on the size of the set ratio) can be controlled in 10 0.1%- +0.3%. According to the number of types to be processed and the amount per hour to choose the appropriate model, the series of products are divided into 42 types. (This product is not suitable for powder and sheet material weighing).