Features for Double screw masterbatch dosers The

metering masterbatch machine is suitable for the automatic proportioning of new materials, secondary materials, masterbatch, or additives, and the error value is not higher than ±1%.

The standard model of metering masterbatch machines cannot be used for the treatment of all kinds of plastic powder masterbatch and the treatment of all kinds of food, chemicals, flammable, explosive, and volatile materials. If the customer's product is an optical industry product, such as PC, PMMA, etc., the standard masterbatch machine model cannot be selected. The part in contact with the raw material needs special treatment, such as the use of food-grade materials and polishing treatment.

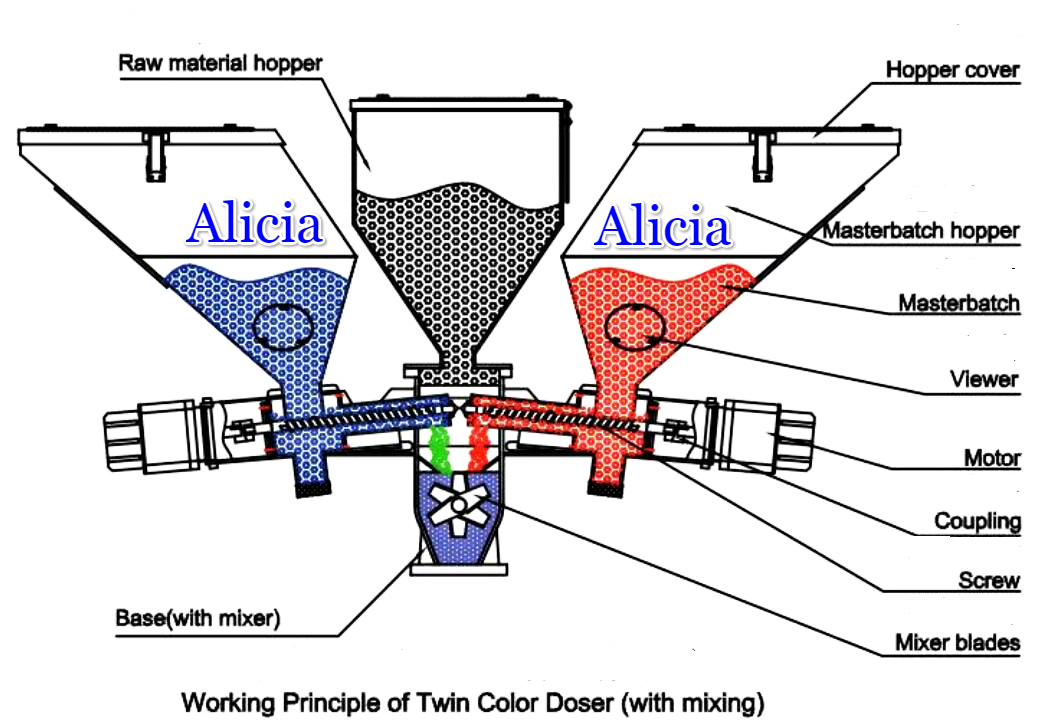

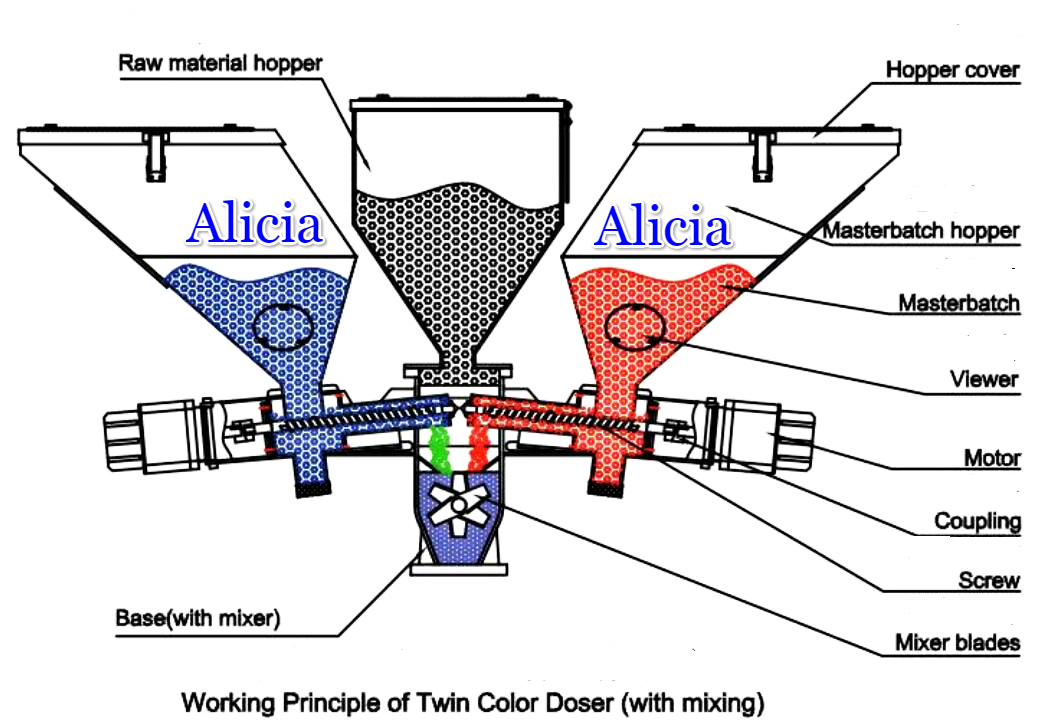

working principle for Double screw masterbatch dosers

working principle for Double screw masterbatch dosers The signal from the control box is transmitted to the motor, the motor starts to rotate, and the screw is driven to rotate through the coupling. The color masterbatch in the hopper falls into the drop rod, is squeezed by the screw, and is conveyed to the base by the screw, so as to achieve the purpose of accurately metering and conveying the color masterbatch.

Standard configuration for Double screw masterbatch dosers 1. It has the function of permanent memory and storage of data;

2. Using DC brushless motor, no maintenance required;

3. Using microcomputer control, intelligent and precise calculation;

4. It can meet the requirements of external signal input at the same time;

5. The screw is chrome-plated, which is durable;

6. Modular assembly structure, easy to disassemble and assemble, easy to clean and exchange;

Optional configuration for Double screw masterbatch dosers 1. When the customer is equipped with a dryer of 100KG or below, a large base is required;

2. The metering masterbatch machine can add up to four masterbatches;

3. Optional touch screen control panel;

4. The main hopper is optional to facilitate customers to add main raw materials.

Product Details

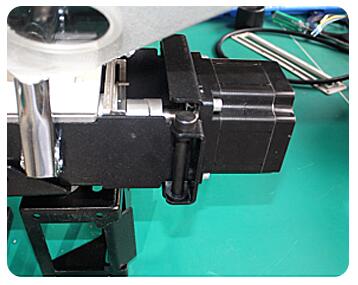

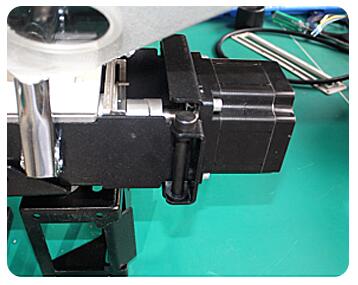

Motor of Volumetric Doser

Using the high accuracy hybrid stepping motor,

Measurement accuracy and output scope.

PLC Panel of Volumetric Doser

The adopted PLC panel shows reliable performance and easy maintenance,

Can store 50sets of formula, can quickly start the machine.

Humanized Design of Volumetric Doser

The large opening on the side of the neck-piece,

large window, and improved static blending.

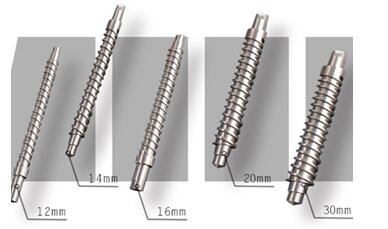

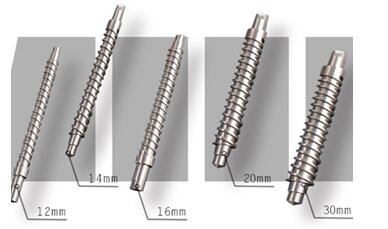

Dosing screw of Volumetric Doser

Dosing screw material is made by 304 stainless steel, and chrome plated for durability;

The specifications are optional 12/14/16/20/30mm.

.

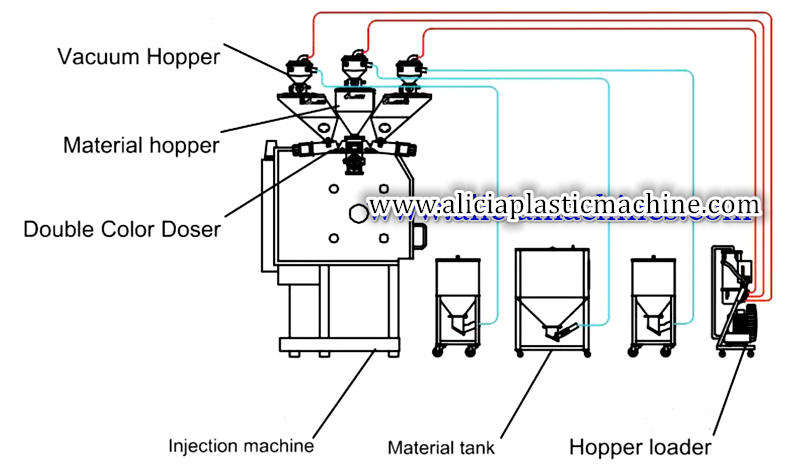

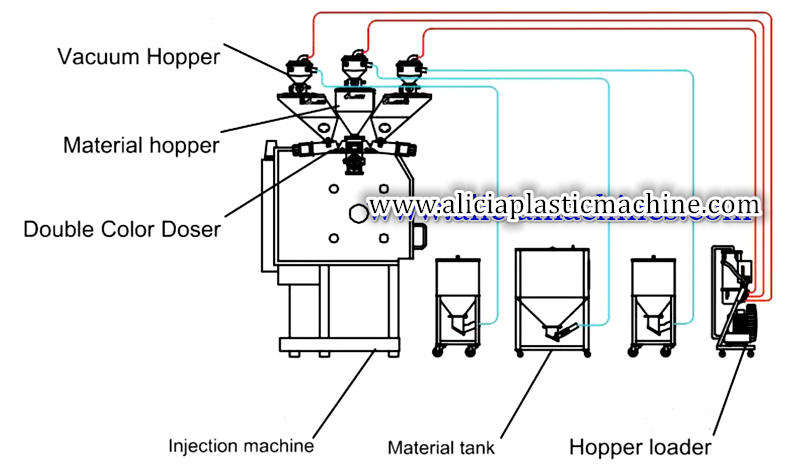

Application for Double screw masterbatch dosers In general, the metering masterbatch machine is directly installed at the inlet of the molding machine. In order to prevent the control box from shaking with the action of the molding machine screw and causing the loosening of related accessories, it is recommended to fix the control box on a bracket. The motor reduction ratio of this product is divided into 30:1 and 50:1, etc. The screw diameter is divided into five types: 12, 16, 20, 25, and 30mm. Six models can be evolved to provide different outputs from 0.1 to 50 kg per hour. For customers to choose. There is also a

two-color masterbatch machine, which can be combined with any two masterbatch machines according to customer needs. Metering masterbatch mixer/ Colors Volumetric Dosers.