air cooled chiller for carbonated soft drink production

The plate heat exchange chiller is characterized by the use of plate heat exchangers. Under the same pressure loss, its heat transfer coefficient is 3-5 times higher than that of tube heat exchangers. It covers an area of One-third of the tube heat exchanger, the heat recovery rate can be as high as 90% or more.

Composition

The plate heat exchange chiller consists of a plate heat exchanger, an intelligent temperature control device, an intelligent electric control device, a circulating pump, a make-up pump, a stabilized expansion tank, a make-up (condensate) tank, filters, valves, meters, sensors, piping bases, etc.

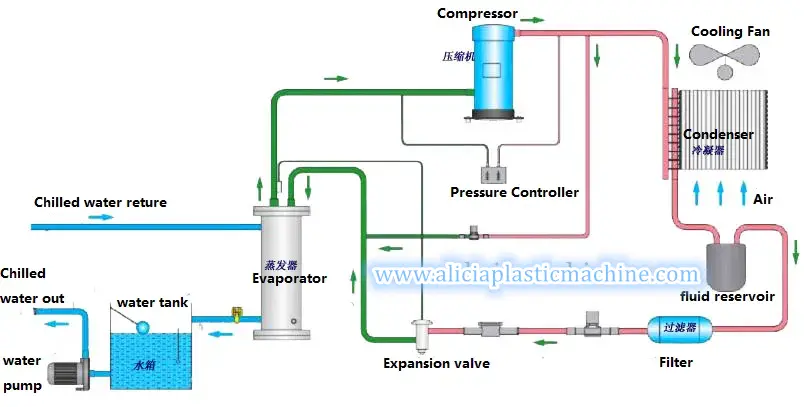

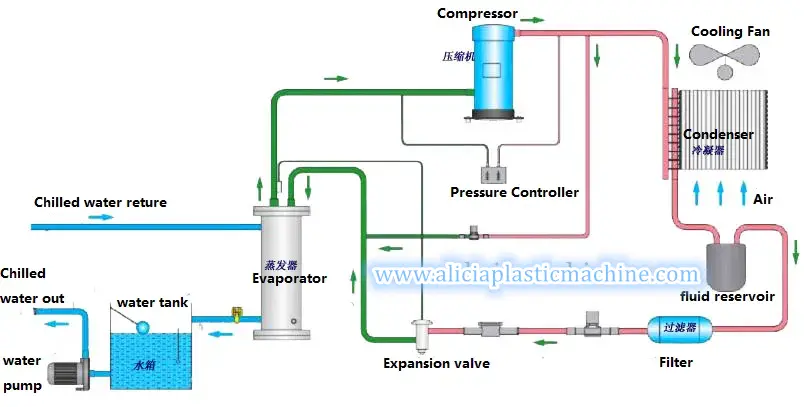

Working principle

Under the control of the temperature control valve, the high-temperature water is sent to the plate heat exchanger unit according to the flow required by the heating system. The heat exchanger heats the heating (air conditioning) return water of the hot user by indirect heat exchange; the heated water first flows through the stainless steel The core decontamination device enters the heat exchanger through the circulating pump and is heated for the user to use, and the cycle starts again and again. The primary heat medium returns to the primary heat supply pipe network after the heat exchange of the plate heat exchanger unit. The water loss of the system is automatically replenished by the water supply pump according to the set pressure to ensure stable and normal operation of the system pressure.

Application:

The plate heat exchange chiller has the advantages of high efficiency, energy-saving, intelligence, automation, etc., and can be widely used in factories, offices, schools, residential quarters, villas and other civil buildings, shopping malls, hotels, restaurants, resorts, and other commercial buildings for heating, air conditioning, and bathing water, domestic water, and winter water for swimming pools can also be used to prepare industrial production process water and various places where heat exchange is required.